Welcome To Us

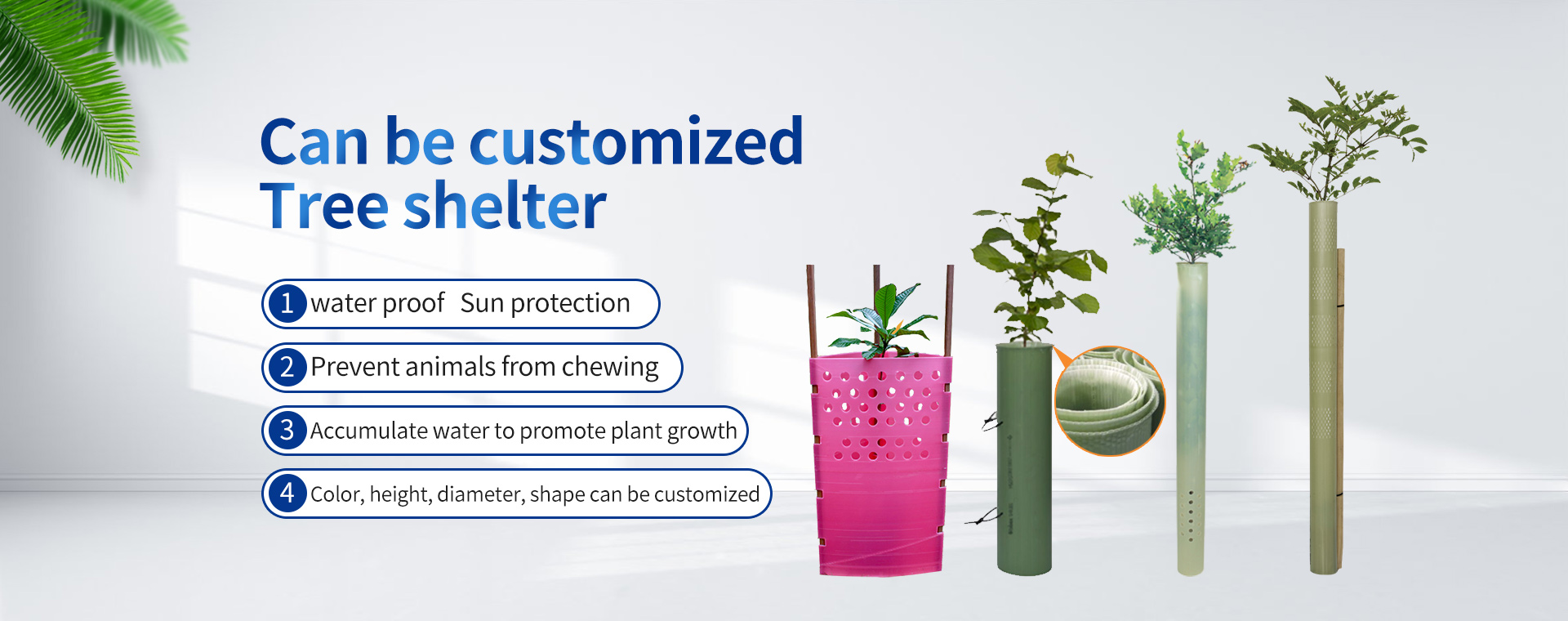

OEM Service Offered Design Service Offered

WHY CHOOSE US

Shandong Runping Plastic Co.,Ltd is one high-tech factory for PP plastic hollow sheet (roll) and Plastic packing boxes with ISO 9001:2008 & RoHs authentication in Weifang city,shandong province,China.

-

Sound insulation and heat insulation

Due to the hollow structure of the plastic hollow sheet, its heat and sound transmission effects are much lower than those of solid sheet. It has good heat insulation and sound insulation effects.

-

Low cost

The first is that the cost of hollow plastic materials is lower than other materials. It will greatly save a lot of costs during the process of purchasing raw materials to finished products.

-

Environmental friendly

It is important to know that environmentally-friendly materials are more concerned all over the world. PP hollow sheet are non-toxic and non-polluting, and can be recycled and reused to make other plastic products.

Popular

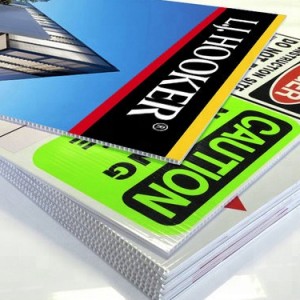

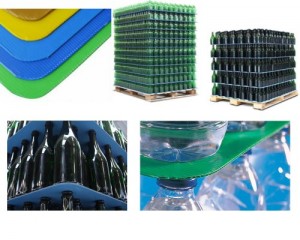

our Products

We hope have good business development with every customer!Welcome to visit our factory!

who we are

●50000 m2+ factory area

●30000MT+ annual output

●2500mm +width H board and X board

260+ trained employees

●16+ automatic extrusion lines

●11+ set of automatic cutting and forming

devices

●5 + automatic colorful print machine

●1.2-13mm+ thickness board

-

Phone

Tel

008613355279991

-

E-mail

E-mail

export@runpingpp.com

-

Whatsapp

Whatsapp

8613355279991

-

WeChat

-

Top